2 Inch Socket Weld Gate Valve Dimensions

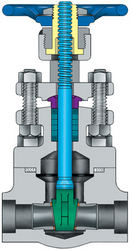

Forged steel conventional port socket weld gate valve.

2 inch socket weld gate valve dimensions. Gate valves welded bonnet full standard port 800 lb 1500 lb. Indicate body bonnet and trim material from section c 5. Specify valve size 2. Size connection type material class weight.

The closure member of gate valves either stops or allows flow through the valve and acts somewhat like the opening or closing of a gate and is called appropriately the gate valve. Size range s nps 1 2 2 dn 15 50 pressure rating asme class 600 standard connections socket weld threaded. The valve face to face dimension is the distance between the 2 ends of flanged ball gate globe plug valves 150 2500 set by asme b16 10. Socket weld flange dimensions are covered in asme b16 5 which covers pipe flanges and flanged fittings for size nps to 24 for above nps 26 to 60 it should be as per asme b16 47.

Often used for oxygen service and other high purity applications these valves come cleaned and bagged. Size inch 1 4 3 8 1 2 3 4 1 1 1 4 1 1 2 2 mm 6 10152025324050 a inch 3 15 3 15 3 54 4 33 5 5 5 28 6. Specify as a suffix string after section d or e any body bonnet. Marking mss sp25 outside screw and yoke os y self aligning two piece packing gland spiral wound gasket integral backseat socket weld ends to asme b16 11 screw ends npt to asme b1 20 1 butt welding ends to asme b16 25.

Select valve type desired from section b 4. Select valve description from section a 3. Socket weld ends to asme b16 11 screwed ends npt to asme b1 20 1 butt welding ends to asme b16 25 ratings. Select special requirement s from section e 7.

Select end configuration from section d 6. Vogt valves 2 in. For easy maintenance they have a three piece bolted body that disassembles inline so you can access internal components without removing welded connections. Gate valve description gate valves are primarily designed for on off services when a straight line flow of fluid and minimum restriction is desired.

Insert unthreaded pipe into the socket ends and weld to create a permanent leak tight connection. Ansi asme b16 11 thread. Ansi asme b1 20 1 butt weld. During a dimensional inspection of socket weld flange you should check for.

End connections socket weld.